Thermal spraying can provide thick coatings approx.

Ceramic welding wiki.

Some elements such as carbon or silicon may be considered ceramics ceramic materials are brittle hard strong in compression and weak in shearing and tension.

Thickness range is 20 microns to several mm depending on the process and feedstock over a large area at high.

Welding steel would require direct current electrode negative dcen.

They withstand chemical erosion that occurs in other materials subjected to acidic or caustic environments.

Different materials are used as media including ceramic balls flint pebbles and stainless steel balls.

X ray quality back beads on root pass.

The feedstock coating precursor is heated by electrical plasma or arc or chemical means combustion flame.

Our backing can support a variety of welding ceramic welding jobs as.

Ultra high temperature ceramics uhtcs are a class of refractory ceramics that offer excellent stability at temperatures exceeding 2000 c being investigated as possible thermal protection system tps materials coatings for materials subjected to high temperatures and bulk materials for heating elements.

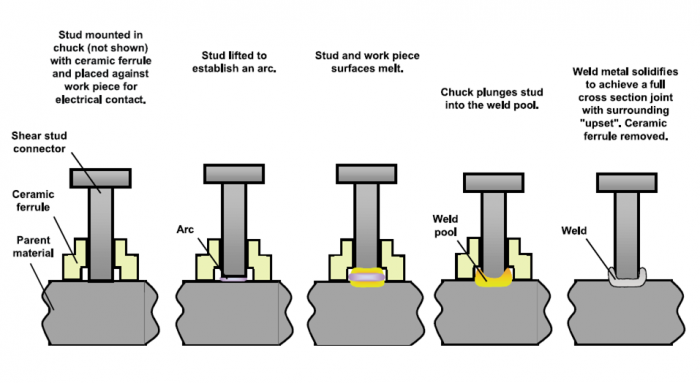

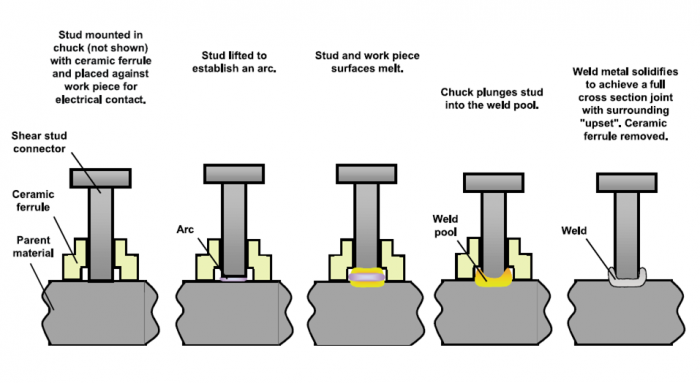

Stud welding uses a flux tip and a ferrule a ceramic ring which concentrates the heat prevents oxidation and retains the molten metal in the weld zone.

Welding aluminium for example would usually require direct current electrode positive dcep.

Ceramic welding benefits include.

Gas tungsten arc welding gtaw also known as tungsten inert gas tig welding is an arc welding process that uses a non consumable tungsten electrode to produce the weld the weld area and electrode is protected from oxidation or other atmospheric contamination by an inert shielding gas argon or helium and a filler metal is normally used though some welds known as autogenous welds or.

Create a better managed and better suited ceramic manufacturing project by beginning with the proper welding materials.

Our ceramic weld backing offers complete joint penetration and adhesion.

Broadly speaking uhtcs are borides carbides nitrides and oxides of early.

In addition to melting the base metal a filler material is typically added to the.

To learn more about our ceramic weld backing contact us or request a free quote today.

Root weld and fill in one pass.

Deposit more weld metal.

Eliminate defeats and re work.

Alcohol should be avoided when cleaning surfaces as it can degrade the bond.

A ceramic material is an inorganic non metallic often crystalline oxide nitride or carbide material.

Find quality ceramic weld backing for adhesion on all your welding implementations.

Weld one side only.

J b weld can be used to bond surfaces made from metal porcelain ceramic glass marble pvc abs concrete fiberglass wood fabric or paper.

Thermal spraying techniques are coating processes in which melted or heated materials are sprayed onto a surface.

J b weld is a two part epoxy adhesive or filler that can withstand high temperature environments.